Specification:

Specification:

Material to be processed: carbon steel, cold hot rolled pre slit strip coils of weld able grade with max. 0.2% carbon

Type of Production: Round Tubes, Squar, Square and Rectangular Hollow Sections

Round Tube Outside Diameter: Min 50.8, Max 165mm

Square Hollow Section: Min 40x 40, Max 130 x 130 mm

Rectangular Hollow Section: Min 40 x 60, Max 100x 160 mm

Tube Thickness: Min 1.8 Max 6.0 mm

Forming Line Speed: Max 55 m/min

(Square and Rectangular Hollow Shapes are produced at lower speeds depending on side to wall thickness ratio)

Tube Cut Length: Min 4 Max 15meter

Length Accuracy: ± 3mm

Line Composition:

V-shape pre-discharging table (V coil stand)

Hydraulic charging wagon (coil car)

Hydraulic discharging machine (uncoiler)

HydraulicShear and TIG Welder.

Horizontal Strip Accumulator.

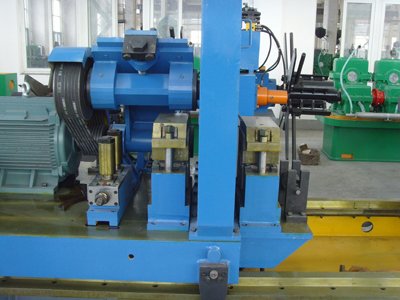

Forming, Welding, Cooling and Sizing Section. Drive Motor: DC 132 kW+ 132 kW

Computer Flying Saw Cut-Off.

Straightener

End Milling and Chamfering Machine

Baling Press

Driven Roller Run Out Table, Inspection table & Collectors.

Solid State H.F. Induction Welder: 400 kW, Solid State Type

Rolls: Rolls are manufactured out of AISI D3 D2 or E52100

Hydraulic Units

Electrical Panels